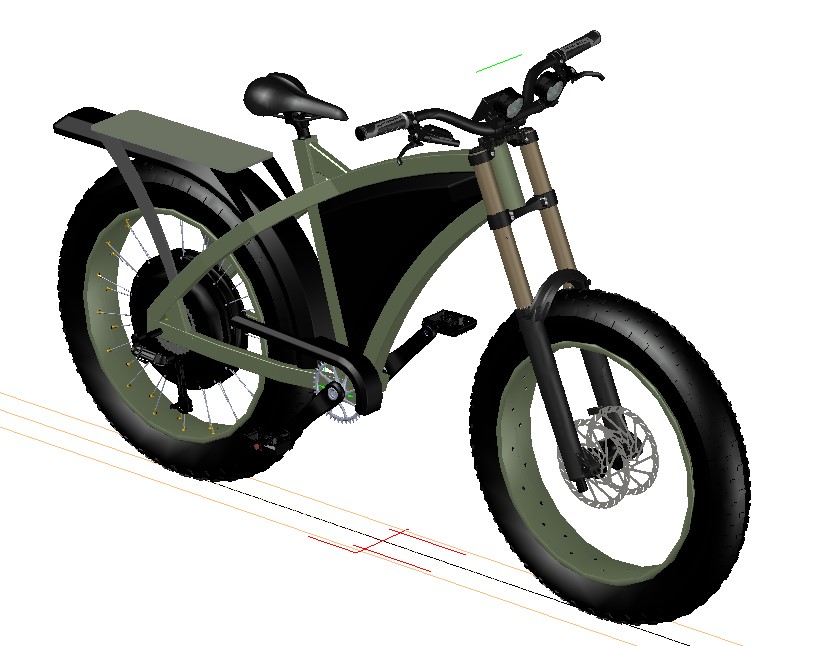

CUSTOM E-BIKE

welding of the bicycle frame - stainless steel.

CUSTOM E-BIKE

Frame designs in all sizes, including individual ones.

CUSTOM E-BIKE

All types of expedition and recreational e-bikes.

Previous

Next

CUSTOM E-BIKES

For whom ?

The idea of custom-building electric bikes according to individual orders is dedicated to:

- who wants a e-bike with a unique design.

who has an interesting project in mind, but is unable to implement it on their own.

- who needs a bike that does not exist at all …

- whose height and weight exceed the capabilities of mass-produced bicycles.

- who is not satisfied with the drive power in serial bikes.

- for anyone who expects more from a bicycle than they can get when buying a ready-made bicycle from a store.

for anyone who requires better drive components

How are they built / designed.

In order:

- We agree on the type of bike, your expectations etc.

- You send us any photos / drawings – inspiration for the project.

- You send us your dimensions – height, weight. Be sure to also describe all health restrictions.

Next step:

At this stage, we present you the estimated costs of building a bicycle, and the time od realisation. We start work...If you accept the quote and time, we start working on the project.

Work shedule

Before that, however, we will provide you with a work schedule. For example:

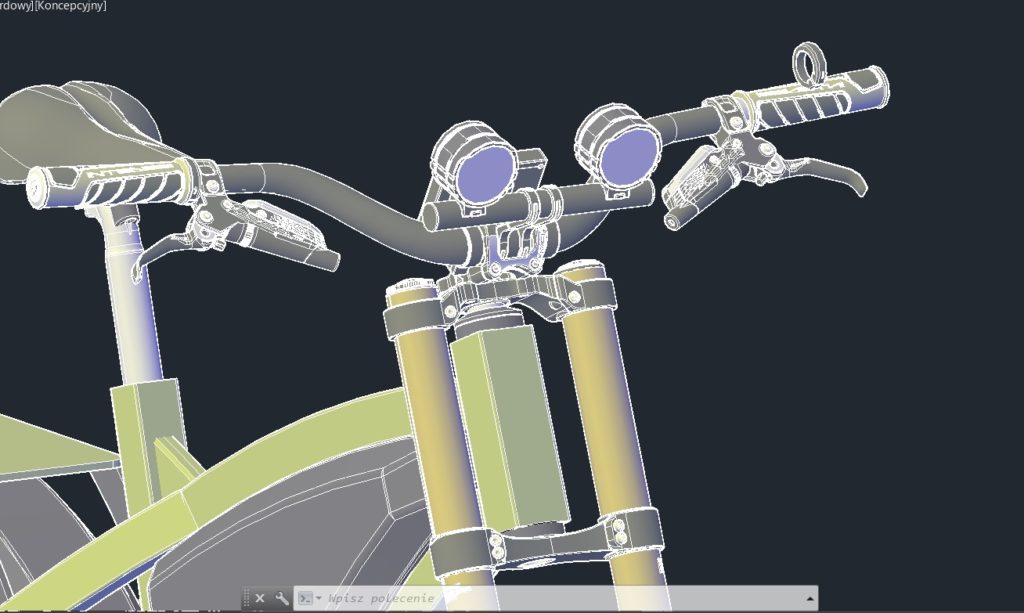

- Preliminary design (3D) development – 2 weeks.

- Development of the final design + visualizations. – 2 weeks.

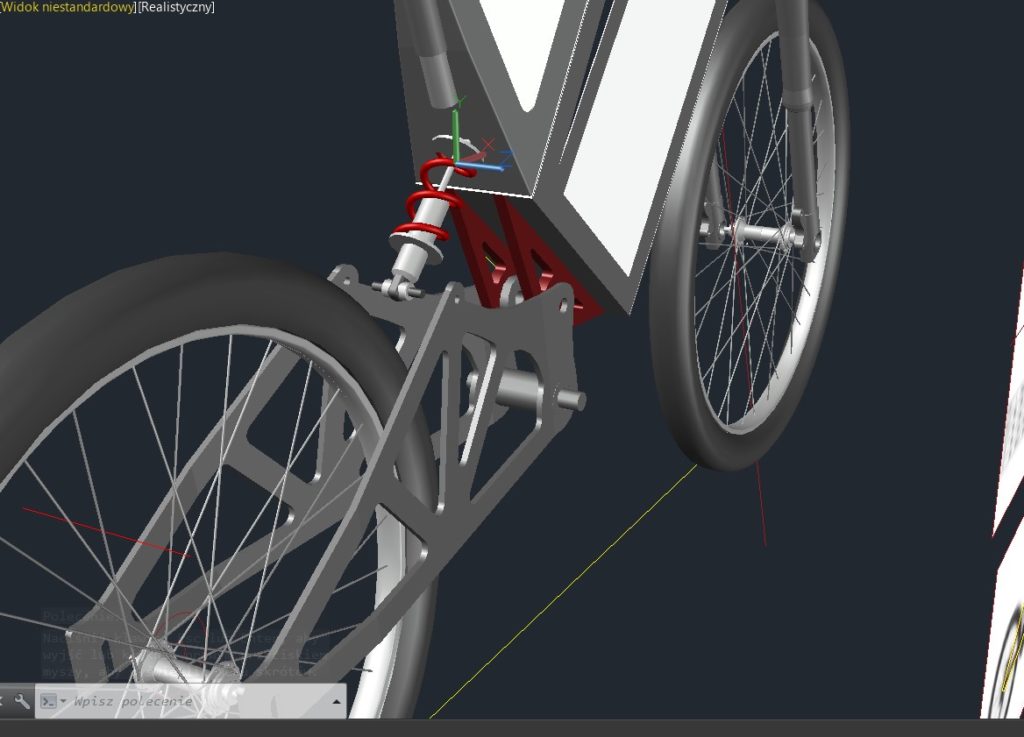

- Fabrication of the bicycle frame. – 4 weeks

- Production of elements in 3D printing technology (all housings). – 3 weeks.

- Trial assembly – steering, drive components, housing, etc. – 2 weeks.

Disassembly for painting work - 1 week.- Painting work ( frame etc) 2 weeks.

- Final assembly of the whole. – 3 weeks.

On-the-go tests. - 2 weeks.

Financial settlement.

Settlement takes place in the AGILE system, i.e. on an ongoing basis, along with the progress of work.

Thanks to this method, you always pay only a small part of the total amount due, keeping the progress of work under control.

For example:

- Design development – 5% of the total value.

Frame performance - 10% of the total value.

etc…etc…

Note: Payment must be made prior to the commencement of a given stage of work.

The most important information:

- Custom bicycle construction is not a cheaper alternative to buying a ready-made, mass-produced bicycle!

The price of a bicycle built on an individual order is always higher than the price of a bicycle that you can buy in the store. Usually 30-100% higher.

The time of building a custom bike is: - 5-6 weeks if we are building on the basis of the finished frame.

- 12-16 weeks if we need to design and build the frame from scratch.

- 16-20 weeks for extremely complex projects requiring the use of composite technology and 3D printing.

In what technologies we make bicycle frames.

If we start making the frame from scratch, it is always a frame made of high-grade stainless steel.

We do not make aluminum frames! Custom bikes are not built to be made the same as factory-made. Besides - frames made of stainless steel are ...INDESTRUCTIBLE :) And this is not a joke. Every industrial engineer knows this - stainless steel does not suffer fatigue during normal use.

What you gain by commissioning a custom construction of an electric bike.

- A bicycle with electronic equipment (drive components) of a quality unattainable in mass-produced bicycles.

- A drive with a durability of several tens of thousands of kilometers!

- The drive does not require any complicated service. You can do everything yourself.

- Drive components without the effect of „programmable failure rate”.

- A bicycle with electronic equipment (drive components) of a quality unattainable in mass-produced bicycles.

- A drive with a durability of several tens of thousands of kilometers!

- The drive does not require any complicated service. You can do everything yourself.

- Drive components without the effect of „programmable failure rate”.

In the custom e-bikes:

- You can program the drive control computer yourself, and change the drive parameters. It is so simple you can do it in minutes.

You have a battery with a capacity of 2 - 3 times more than a mass-produced e-bike.

We build all custom bikes as two-system. - Configuration for driving on public roads.

- Off-road configuration.

Switching between modes is achieved by turning the key in the ignition switch only. In off-road mode, you have full propulsion performance at your disposal. 1500 ... 3000 ... 5000 Watt as much as you want.

Summary:

To design and build an e-bike from scratch, is need a lot of knowledge and experience in many areas of engineering.

We have been designing for 30 years. We have worked in industries - aviation, boatbuilding, furniture, electronics, welding, and complex light alloy structures.

Nevertheless, we are still learning ... Just designing a frame for a bicycle can take over 100 hours of design work.

We write about it so you won't be surprised that the price of a custom-built bike is much higher than that of a mass-produced bike. So... If you have spotted a bike somewhere that costs, for example, EUR 2,000, but you would like a similar one, but with a more powerful drive and adapted to your height, in the color you choose, etc., take into account that it will cost, for example, EUR 3-4 thousand.

Of course, you will also have to wait several weeks for your custom-build e-bike.